Technologies

Our solution

ready-to-use MEGCs with maximum hydrogen purity

Patented technology enables immediate use

HYKONIS multiple element gas containers (MEGCs) are ready for immediate use: they are delivered with Type-IV containers filled with pure hydrogen.

Our patented process enables each container to undergo vacuum-assisted leak testing under operating pressure, using 100% hydrogen – before integration into the system.

This saves time and complies with the requirements of ISO 13807, Chapter 7.3.3. An initial leak test by our customers is no longer necessary. The result: a system that is technically convincing and economically viable.

99.99 % purity straight from the factory – with no flushing loss

An additional advantage is that our vacuum drying process completely removes moisture and foreign

Energy efficient and low-maintenance – through cascaded gas recovery

Our system makes cascaded gas recovery possible. This reduces compressor and system performance by up to 90%, while at the same time cutting process times by a factor of ten.

This significantly lowers both energy consumption and maintenance costs.

Precision and safety

in gas logistics

Your HYKONIS advantages

at a glance

Economic viability

Attractive acquisition and operating costs plus zero-loss filling allow for a quick return on investment

Ready for immediate use

The MEGC is fully functional when it leaves the factory

Maximum purity

99.99 % hydrogen purity (fuel cell grade) when it leaves the factory

Tested safety

100% leak test with hydrogen as the test gas

Relaxation of standard

No need for the testing specified by ISO 13807, chapter 7.3.3

Safety

Vacuum drying with no residual moisture or foreign gases

Efficient operation

No flushing process, no loss of gas, significantly reduced hydrogen consumption

Technical background

Why HYKONIS does what it does

Previous process – dilution with cyclic pressure flushing

The initial filling of Type IV containers is usually based on the principle of dilution. To begin with, there is atmospheric air in the container. This consists of approx. 78% nitrogen and 21% oxygen. To avoid any risk of explosion, the vessel is flushed with nitrogen until the oxygen content has been reduced to below 4%.

Following this, it is filled with hydrogen, which – along with the remaining gas mixture – is then discharged by releasing the pressure.

As hydrogen is lighter than nitrogen, it escapes more readily, reducing the efficiency of dilution. This process, known as cyclic pressure flushing, must be repeated until the nitrogen content is below 100 ppm.

The procedure is:

- Time-consuming (6-8 hours)

- Manually intensive

- Wasteful, as the contaminated hydrogen cannot be reused

The HYKONIS solution

Filling via Vacuum Chamber

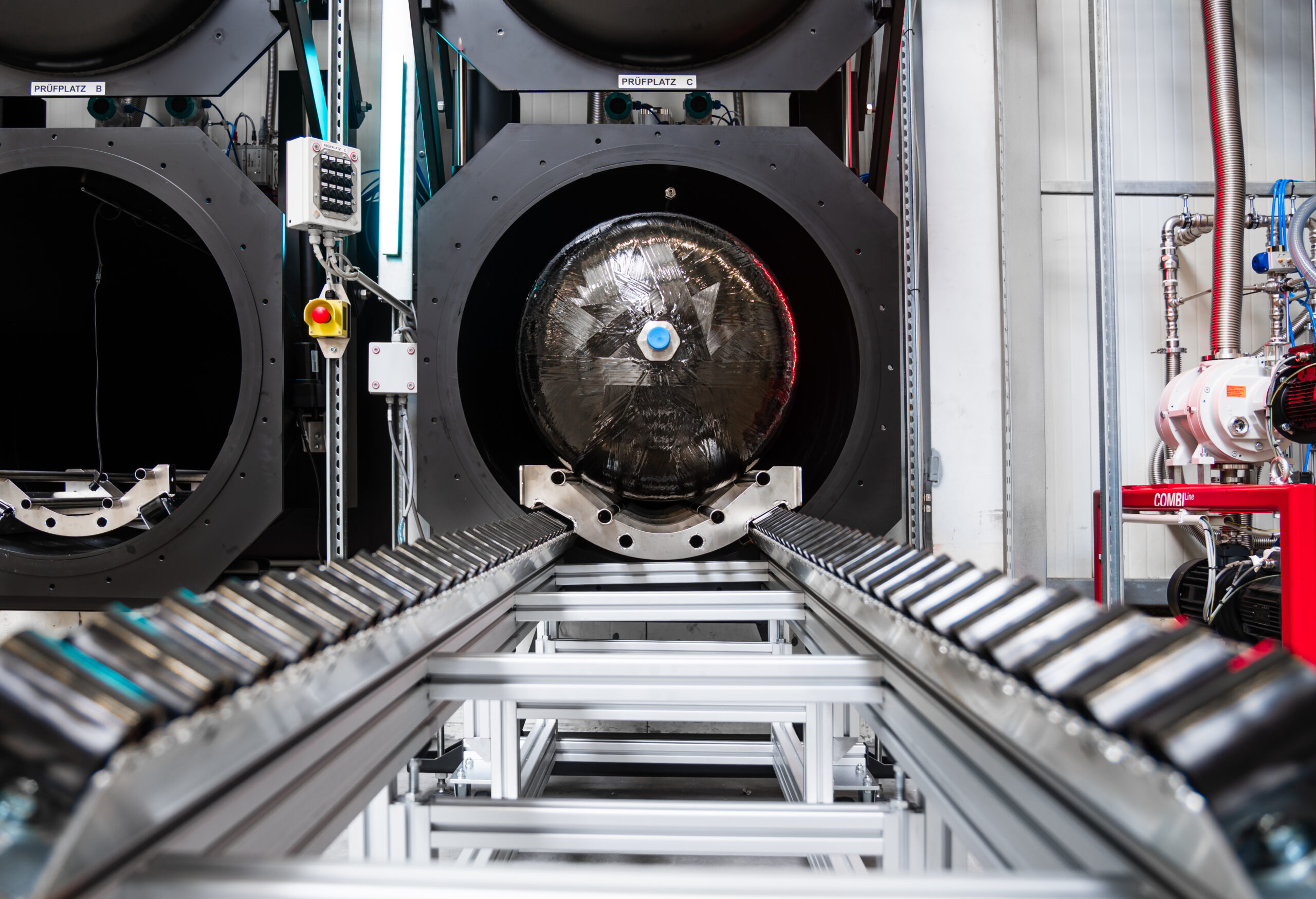

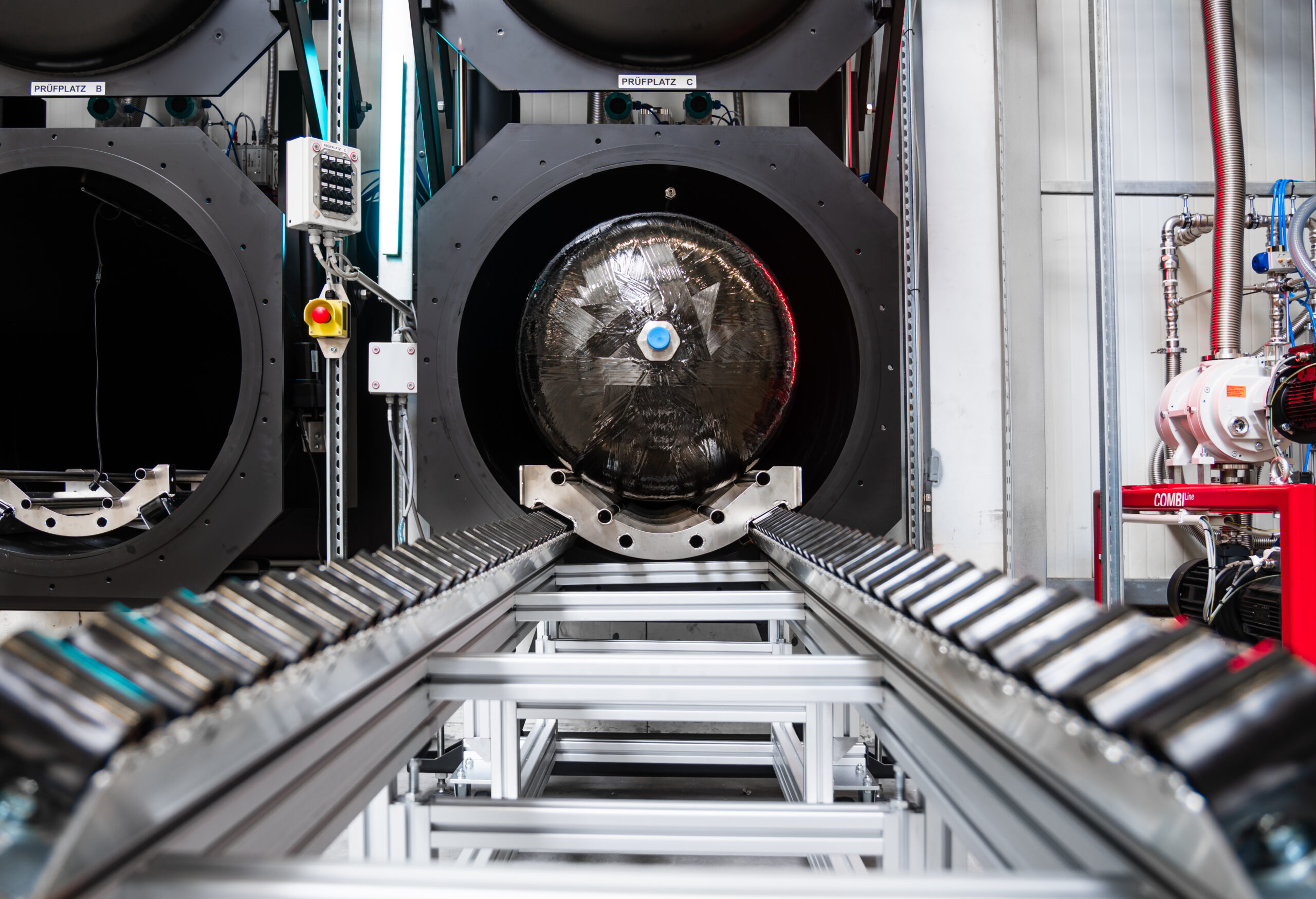

HYKONIS uses a patented process in which leak testing and initial filling are carried out in a specially developed vacuum chamber – quickly, safely, and without loss.

The challenge posed by Type IV containers:

They are composed of a CFRP shell (carbon fiber reinforced plastic) with a plastic liner inside. While the shell can withstand high internal pressure, a vacuum in the interior at ambient pressure on the outside would cause the liner to collapse.

The solution:

The sealed container is placed in an evacuated chamber.

- As the internal pressure remains normal, relative overpressure initially builds up in the vessel

- After opening, the air escapes in a controlled manner

- Even when the chamber is completely evacuated, there is a vacuum both inside and outside – with no difference in pressure

The result:

- No damage to the liner

- No flushing process is required

- Pure hydrogen can be fed straight in